204A1024

Brand: JUNT, a professional manufacturer of grooved pipe fittings for global markets.

Origin: Manufactured in Weifang, Shandong Province, China.

Model/Type: Rigid Coupling for grooved pipe connection systems.

Standards & Certification: Designed to meet ANSI, ASTM, ISO standards; FM, UL, and CE available.

Payment Methods: T/T, L/C at sight, and other negotiable international payment terms.

Origin: Manufactured in Weifang, Shandong Province, China.

Model/Type: Rigid Coupling for grooved pipe connection systems.

Standards & Certification: Designed to meet ANSI, ASTM, ISO standards; FM, UL, and CE available.

Payment Methods: T/T, L/C at sight, and other negotiable international payment terms.

- Connection Method

- Application Scenarios

- Materials & Surface Treatment

-

Connection Method

Grooved fitting blind flanges are connected to other fittings via grooved connection technology, which is simple and fast, requires no welding, and is easy to disassemble and reuse.

-

Application Scenarios

Widely used in industrial fields such as petrochemicals, water treatment, energy and power. It is applied to decommission a certain section of pipe, isolate part of the system during maintenance, seal the ports of newly built pipes to prevent foreign matter from entering, and plug pipes before pressure testing.

-

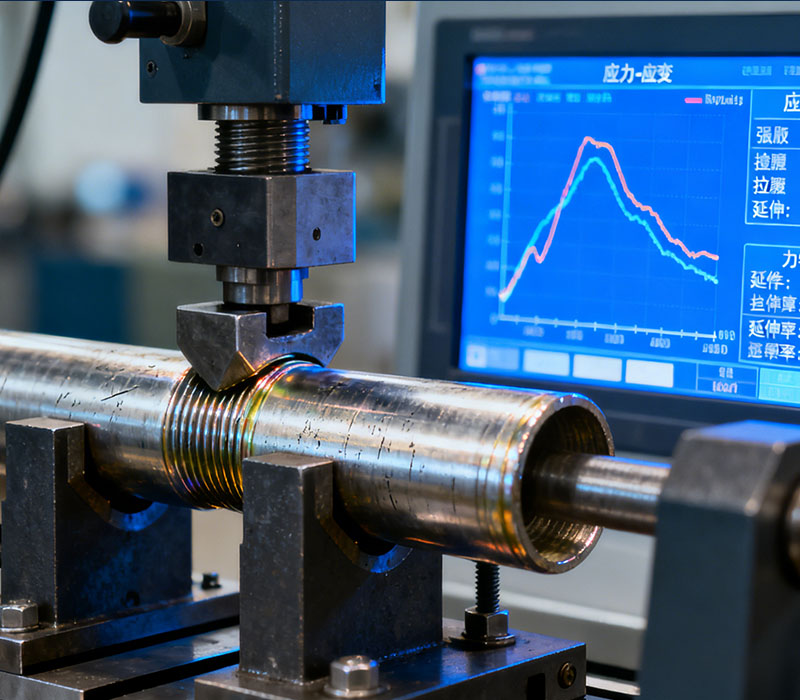

Materials & Surface Treatment

Common materials include carbon steel and stainless steel. According to different service environments, surface treatments such as electrostatic spraying, hot-dip galvanizing, painting and dacromet coating can be adopted to improve corrosion resistance and other properties.

- Definition & Types: Also known as a flange cover, blank flange or pipe plug, it is a flange with no hole in the middle. It is mainly divided into two types: ordinary blind flanges and figure-8 blind flanges. An ordinary blind flange is a solid circular plate with a handle, while a figure-8 blind flange has a blind flange on one end and a restriction ring on the other.

- Functions: Its main function is to seal the pipe system, preventing fluid leakage where circulation is unnecessary, and it can serve as a temporary or permanent plugging device. It can withstand a certain working pressure to ensure the safety and reliability of the pipe system. It is also used to isolate the system for maintenance or plug the end of a pipe.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Design and Consulting Services

Professional advice on grooved fittings material selection, installation guidance, construction code interpretation, as well as maintenance and troubleshooting.

Comprehensive Product Supply Services

Providing basic pipe fittings such as elbows, tees, reducers, as well as core accessories like clamps and sealing rings. Supports customized surface treatments including plastic coating and galvanizing.

After-sales support services

Include 24-hour technical consultation, product maintenance advice, and dedicated maintenance plans for high-demand projects. Additionally, we provide rapid disassembly and replacement guidance for faulty pipe components.

Customer Support

Customer Support:

Providing assistance to clients via multiple channels (phone, email, live chat) to address inquiries, resolve issues, and offer guidance on products or services.

Technical Assistance:

Offering expert help for troubleshooting technical problems related to products, software, or systems, ensuring smooth operation for users.

Billing and Payment Services:

Managing invoicing, processing payments through various methods (credit cards, bank transfers), and handling refunds or adjustments as needed.

Account Management:

Maintaining client accounts, updating information, tracking usage or purchases, and providing personalized support to foster long-term relationships.

Training and Onboarding:

Delivering tutorials, workshops, or materials to help clients or new users learn how to effectively use products, tools, or services.

Feedback and Improvement Services:

Collecting customer opinions through surveys or direct communication, analyzing feedback, and using insights to enhance products, services, or processes.