Rigid coupling

Standards & Certification: Designed to meet ANSI, ASTM, ISO standards; FM, UL, and CE available.

Payment Methods: T/T, L/C at sight, and other negotiable international payment terms.

Supply Capacity: Stable mass production capability to support large-volume and long-term orders.

- Rigid design ensures strong pipe alignment, high sealing performance, and leak-free connection.

- Made from high-strength ductile iron with corrosion-resistant coatings for long service life.

- Easy and fast installation, widely used in fire protection, water supply, HVAC, and industrial piping systems.

-

Core Advantages

Provides a rigid and fixed pipe connection that prevents angular deflection, axial movement, and rotation after installation.

Ensures excellent sealing performance and long-term stability, comparable to welded or flanged joints.

Enables faster installation and easier maintenance compared with traditional pipe connection methods, reducing labor cost downtime.

-

Design Drawings

The coupling consists of a ductile iron housing, high-quality elastomer gasket, and high-strength bolts and nuts.

Precision-designed groove profile ensures accurate pipe alignment and uniform gasket compression.

Detailed dimensional drawings and technical schematics are available to support engineering design and project installation.

According to different situations,the appearance can be dealed with epoxy powder,galvanized,paint,dacromet or your requirements.

| Nominal Size mmin |

Pipe O.D mm/in |

Working Pressure PSI/Mpa |

Bolt Size | Dimensions mm/in | ||

| No.-Size mm |

L | H | ||||

| 25 1 |

33.7 1.327 |

300 2.07 |

2-M10*45 | 55.6 2.188 |

98 3.858 |

44 1.732 |

| 32 1 1/4 |

42.4 1.669 |

300 2.07 |

2-M10*45 | 66 2.598 |

107 4.213 |

44 1.732 |

| 40 11/2 |

48.3 1.9 |

300 2.07 |

2-M10*45 | 74 2.913 |

115 4.527 |

44 1.732 |

| 50 2 |

60.3 2.374 |

300 2.07 |

2-M10*55 | 88.4 3.480 |

125 4.921 |

46 1.732 |

| 65 21/2 |

73.0 2.875 |

300 2.07 |

2-M10*55 | 102.2 4.024 |

140 5.512 |

46 1.772 |

| 65 21/2 |

76.1 3 |

300 2.07 |

2-M10*55 | 102.2 4.024 |

140 5.512 |

46 1.772 |

| 80 3 |

88.9 3.5 |

300 2.07 |

2-M10*60 | 117.4 4.622 |

154 6.063 |

46 1.772 |

| 100 4 |

108 4.25 |

300 2.07 |

2-M12*65 | 138.8 5.466 |

184 7.244 |

48 1.889 |

| 100 4 |

114.3 4.5 |

300 2.07 |

2-M12*65 | 146.6 5.772 |

190 7.480 |

48 1.889 |

| 125 5 |

133 5.25 |

300 2.07 |

2-M12*75 | 158 6.220 |

212 8.346 |

48 1.889 |

| 125 5 |

139.7 5.5 |

300 2.07 |

2-M12*75 | 171.2 6.740 |

220 8.661 |

48 1.889 |

| 125 5 |

141.3 5.56 |

300 2.07 |

2-M12*75 | 171.2 6.740 |

220 8.661 |

48 1,889 |

| 150 6 |

159 6.25 |

300 2.07 |

2-M12*75 | 192 7.559 |

240 9.448 |

48 2.008 |

| 150 6 |

165.1 6.5 |

300 2.07 |

2-M12*75 | 196.2 7.724 |

244 9.606 |

48 2.008 |

| 150 6 |

168.3 6.625 |

300 2.07 |

2-M12*75 | 199.4 7.850 |

246 9.685 |

48 2.008 |

| 200 8 |

219.1 8.625 |

300 2.07 |

2-M16*85 | 256.4 10.024 |

326 12,835 |

58 2.283 |

| 250 10 |

273 10.748 |

300 2.07 |

2-M20*100 | 316 12.441 |

426 16.771 |

64 2.520 |

| 300 12 |

323.9 12.75 |

300 2.07 |

2-M22*130 | 380 14.961 |

470 18.504 |

65 2.559 |

Application Fields

Widely used in fire protection and sprinkler systems for commercial, industrial, and residential buildings.

Suitable for HVAC, water supply, drainage, and water treatment piping systems.

Applied in industrial pipelines such as factories, power plants, oil & gas auxiliary systems, and infrastructure projects.

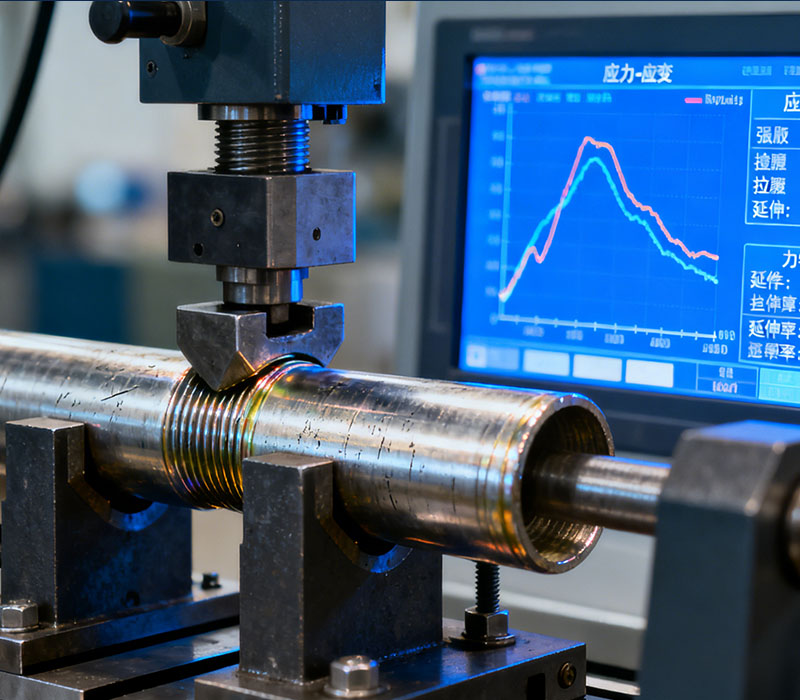

Factory Images

Modern manufacturing facilities equipped with automated casting, CNC machining, and surface treatment lines.

Strict in-house inspection processes including dimensional checks, pressure testing, and visual inspection.

Organized assembly and packaging workshops ensure consistent quality and efficient order fulfillment.

Certificates & Certification

Products are manufactured in compliance with international standards such as ANSI, ASTM, and ISO.

Certifications including FM, UL, and CE are available to meet global market requirements.

Full traceability and quality control documentation are provided to support project approval and audits.

OEM / ODM Customization Options

OEM branding options including logo casting, laser marking, and customized packaging design.

ODM support for customized sizes, pressure ratings, gasket materials, and surface coatings.

Flexible customization solutions to meet regional standards, special applications, and project-specific requirements.

Partner Brands & Collaboration

Long-term cooperation with international distributors, contractors, and system integrators.

Products supplied to fire protection, construction, plumbing, and industrial engineering brands worldwide.

Trusted partner for large-scale projects, long-term supply agreements, and repeat orders.

Packaging Information

Standard export packaging using strong cartons, wooden pallets, or steel-reinforced packaging.

Protective materials applied to prevent corrosion, impact damage, and deformation during transportation.

Customized packaging solutions available according to customer logistics and branding requirements.

FAQ

Q1: What size range is available for the rigid coupling?

A: Standard sizes range from 1″ to 12″, with other sizes available upon request.

Q2: What materials and coatings are offered?

A: Made from high-strength ductile iron, with coatings such as painted, galvanized, or epoxy for corrosion resistance.

Q3: Can the product meet international certification requirements?

A: Yes, the rigid coupling can be supplied with FM, UL, CE, and ISO-related certifications depending on market needs.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Design and Consulting Services

Comprehensive Product Supply Services

After-sales support services